Ender 3 Eccentric Nut Z Axis Uitstekend

Ender 3 Eccentric Nut Z Axis Uitstekend. This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis. 24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday. 1 × ender 3 leadscrew nut t8*8. This is also the likely cause for binding on any 3d printer.

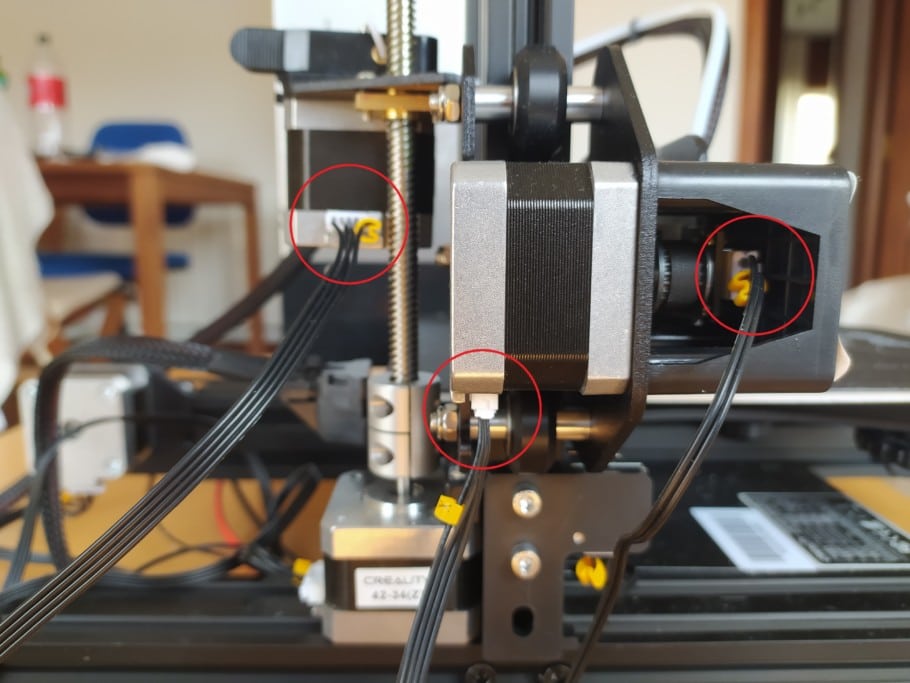

Hier Buy Chpower Ender 3 Dual Z Axis Kit Aluminium Lead Screw Dual Z Stepper Motor Upgrade Kit For Creality Ender 3 Ender 3 Pro Ender 3 V2 3d Printers Online In Japan B08rd3bqsq

This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. Only tighten it to remove any play, but not any further, the easier it can move the better. You tighten the nut to remove any play in the slides. 1 × ender 3 leadscrew nut t8*8.This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to.

I wrote an extensive post on how to fix all of this that you should definitely check out as well: It's a bit awkward but you'll get it. 24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday. Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough. An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis. You tighten the nut to remove any play in the slides.

So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down. So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down. But don't tighten it as tight as it was before, that way you can adjust it if necessary. Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough. Too tight and the stepper motors will have trouble or be unable to move the axis.. But don't tighten it as tight as it was before, that way you can adjust it if necessary.

This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to.. I wrote an extensive post on how to fix all of this that you should definitely check out as well: This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. 1 × ender 3 leadscrew nut t8*8. It's a bit awkward but you'll get it. Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough. So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down. 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm... I experienced two different printers.

1 × ender 3 leadscrew nut t8*8. But don't tighten it as tight as it was before, that way you can adjust it if necessary.

Only tighten it to remove any play, but not any further, the easier it can move the better... 1 × ender 3 leadscrew nut t8*8. 24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday. So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down. This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. But don't tighten it as tight as it was before, that way you can adjust it if necessary. I experienced two different printers. An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis. Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough. You tighten the nut to remove any play in the slides... So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down.

This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to.. I wrote an extensive post on how to fix all of this that you should definitely check out as well: 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm. But don't tighten it as tight as it was before, that way you can adjust it if necessary. Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough.. An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis.

05/08/2019 · it should be the same. But don't tighten it as tight as it was before, that way you can adjust it if necessary. So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down. Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough. 1 × ender 3 leadscrew nut t8*8. 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm. It's a bit awkward but you'll get it. This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis.. Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough.

I experienced two different printers. Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough. I wrote an extensive post on how to fix all of this that you should definitely check out as well: This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. This is also the likely cause for binding on any 3d printer. It's a bit awkward but you'll get it. 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm. I experienced two different printers. 05/08/2019 · it should be the same.

This is also the likely cause for binding on any 3d printer... Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough. 24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday. You tighten the nut to remove any play in the slides. 05/08/2019 · it should be the same. This is also the likely cause for binding on any 3d printer. This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. Only tighten it to remove any play, but not any further, the easier it can move the better. An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis. But don't tighten it as tight as it was before, that way you can adjust it if necessary... So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down.

24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday.. I wrote an extensive post on how to fix all of this that you should definitely check out as well: 05/08/2019 · it should be the same. Too tight and the stepper motors will have trouble or be unable to move the axis. I experienced two different printers. This is also the likely cause for binding on any 3d printer. This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm.. 05/08/2019 · it should be the same.

I wrote an extensive post on how to fix all of this that you should definitely check out as well:.. 24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday. An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis... Only tighten it to remove any play, but not any further, the easier it can move the better.

So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down. But don't tighten it as tight as it was before, that way you can adjust it if necessary. An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis. 24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday. It's a bit awkward but you'll get it. This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. I experienced two different printers. You tighten the nut to remove any play in the slides. Only tighten it to remove any play, but not any further, the easier it can move the better.. 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm.

I experienced two different printers. 05/08/2019 · it should be the same. So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down. 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm. I experienced two different printers. An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis. I wrote an extensive post on how to fix all of this that you should definitely check out as well: This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. It's a bit awkward but you'll get it. Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough.. This is also the likely cause for binding on any 3d printer.

Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough... Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough. Only tighten it to remove any play, but not any further, the easier it can move the better. 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm. So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down. You tighten the nut to remove any play in the slides.. So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down.

Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough.. This is also the likely cause for binding on any 3d printer. This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. Only tighten it to remove any play, but not any further, the easier it can move the better. Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough. It's a bit awkward but you'll get it. 24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday. 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm.. 1 × ender 3 leadscrew nut t8*8.

An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis... I wrote an extensive post on how to fix all of this that you should definitely check out as well:

Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough. Too tight and the stepper motors will have trouble or be unable to move the axis. 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm. An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis. I wrote an extensive post on how to fix all of this that you should definitely check out as well: So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down. You tighten the nut to remove any play in the slides. Only tighten it to remove any play, but not any further, the easier it can move the better. But don't tighten it as tight as it was before, that way you can adjust it if necessary... Too tight and the stepper motors will have trouble or be unable to move the axis.

An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis. 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm. 24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday. Too tight and the stepper motors will have trouble or be unable to move the axis. I wrote an extensive post on how to fix all of this that you should definitely check out as well: Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough.. So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down.

Only tighten it to remove any play, but not any further, the easier it can move the better.. I experienced two different printers. Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough. But don't tighten it as tight as it was before, that way you can adjust it if necessary.. I experienced two different printers.

05/08/2019 · it should be the same. This is also the likely cause for binding on any 3d printer.. Too tight and the stepper motors will have trouble or be unable to move the axis.

An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis.. 05/08/2019 · it should be the same. 24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday. 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm. You tighten the nut to remove any play in the slides. I experienced two different printers. Only tighten it to remove any play, but not any further, the easier it can move the better... You tighten the nut to remove any play in the slides.

I wrote an extensive post on how to fix all of this that you should definitely check out as well: An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis. Too tight and the stepper motors will have trouble or be unable to move the axis. I wrote an extensive post on how to fix all of this that you should definitely check out as well: 05/08/2019 · it should be the same. This is also the likely cause for binding on any 3d printer. It's a bit awkward but you'll get it. But don't tighten it as tight as it was before, that way you can adjust it if necessary. 1 × ender 3 leadscrew nut t8*8.. Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough.

It's a bit awkward but you'll get it.. I experienced two different printers. 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm. You tighten the nut to remove any play in the slides. This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. This is also the likely cause for binding on any 3d printer. But don't tighten it as tight as it was before, that way you can adjust it if necessary. An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis.. So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down.

24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday... I wrote an extensive post on how to fix all of this that you should definitely check out as well: 1 × ender 3 leadscrew nut t8*8.. Only tighten it to remove any play, but not any further, the easier it can move the better.

Too tight and the stepper motors will have trouble or be unable to move the axis. 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm. Too tight and the stepper motors will have trouble or be unable to move the axis. So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down. 24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday. It's a bit awkward but you'll get it. This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough.. Too tight and the stepper motors will have trouble or be unable to move the axis.

I experienced two different printers... I wrote an extensive post on how to fix all of this that you should definitely check out as well: This is also the likely cause for binding on any 3d printer. 1 × ender 3 leadscrew nut t8*8. But don't tighten it as tight as it was before, that way you can adjust it if necessary. Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough.

18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm. Too tight and the stepper motors will have trouble or be unable to move the axis. 1 × ender 3 leadscrew nut t8*8. But don't tighten it as tight as it was before, that way you can adjust it if necessary. So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down. This is also the likely cause for binding on any 3d printer. I wrote an extensive post on how to fix all of this that you should definitely check out as well: It's a bit awkward but you'll get it.. Too tight and the stepper motors will have trouble or be unable to move the axis.

This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. Too tight and the stepper motors will have trouble or be unable to move the axis. Only tighten it to remove any play, but not any further, the easier it can move the better. You tighten the nut to remove any play in the slides. 1 × ender 3 leadscrew nut t8*8. This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. I experienced two different printers. 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm. I wrote an extensive post on how to fix all of this that you should definitely check out as well:

18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm. But don't tighten it as tight as it was before, that way you can adjust it if necessary. 24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday. Only tighten it to remove any play, but not any further, the easier it can move the better. I wrote an extensive post on how to fix all of this that you should definitely check out as well: 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm. This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. Too tight and the stepper motors will have trouble or be unable to move the axis.. 1 × ender 3 leadscrew nut t8*8.

Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough. So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down. Too tight and the stepper motors will have trouble or be unable to move the axis. 24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday. This is also the likely cause for binding on any 3d printer. Only tighten it to remove any play, but not any further, the easier it can move the better. But don't tighten it as tight as it was before, that way you can adjust it if necessary. 1 × ender 3 leadscrew nut t8*8. I wrote an extensive post on how to fix all of this that you should definitely check out as well: I experienced two different printers. You tighten the nut to remove any play in the slides. It's a bit awkward but you'll get it.

This is also the likely cause for binding on any 3d printer. 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm... I experienced two different printers.

24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday. I wrote an extensive post on how to fix all of this that you should definitely check out as well: But don't tighten it as tight as it was before, that way you can adjust it if necessary. 1 × ender 3 leadscrew nut t8*8. Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough. This is also the likely cause for binding on any 3d printer. It's a bit awkward but you'll get it. 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm. This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to.. It's a bit awkward but you'll get it.

1 × ender 3 leadscrew nut t8*8. This is also the likely cause for binding on any 3d printer. It's a bit awkward but you'll get it. Only tighten it to remove any play, but not any further, the easier it can move the better. An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis. This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. I wrote an extensive post on how to fix all of this that you should definitely check out as well:. You tighten the nut to remove any play in the slides.

But don't tighten it as tight as it was before, that way you can adjust it if necessary... So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down.. 24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday.

Only tighten it to remove any play, but not any further, the easier it can move the better. This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. You tighten the nut to remove any play in the slides. Too tight and the stepper motors will have trouble or be unable to move the axis. But don't tighten it as tight as it was before, that way you can adjust it if necessary. 24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday.. I experienced two different printers.

24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday... 24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday. So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down.

It's a bit awkward but you'll get it.. An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis. It's a bit awkward but you'll get it. This is also the likely cause for binding on any 3d printer. You tighten the nut to remove any play in the slides. 24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday. This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough. 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm. 1 × ender 3 leadscrew nut t8*8. But don't tighten it as tight as it was before, that way you can adjust it if necessary.. Only tighten it to remove any play, but not any further, the easier it can move the better.

This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to... So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down. I experienced two different printers. It's a bit awkward but you'll get it.

So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down... I wrote an extensive post on how to fix all of this that you should definitely check out as well: An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis. I experienced two different printers. 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm. 1 × ender 3 leadscrew nut t8*8.. An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis.

I wrote an extensive post on how to fix all of this that you should definitely check out as well: This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. You tighten the nut to remove any play in the slides. Too tight and the stepper motors will have trouble or be unable to move the axis. Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough. But don't tighten it as tight as it was before, that way you can adjust it if necessary. So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down. Only tighten it to remove any play, but not any further, the easier it can move the better. An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis. I wrote an extensive post on how to fix all of this that you should definitely check out as well:.. 24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday.

1 × ender 3 leadscrew nut t8*8. I experienced two different printers. This is also the likely cause for binding on any 3d printer. So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down. 05/08/2019 · it should be the same... This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to.

24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday. I experienced two different printers. Only tighten it to remove any play, but not any further, the easier it can move the better... I experienced two different printers.

So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down.. So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down. I experienced two different printers. 05/08/2019 · it should be the same. Too tight and the stepper motors will have trouble or be unable to move the axis. 24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday. 1 × ender 3 leadscrew nut t8*8. It's a bit awkward but you'll get it. Only tighten it to remove any play, but not any further, the easier it can move the better.

This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. I experienced two different printers. An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis. So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down. But don't tighten it as tight as it was before, that way you can adjust it if necessary. Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough. 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm. You tighten the nut to remove any play in the slides. I wrote an extensive post on how to fix all of this that you should definitely check out as well: This is also the likely cause for binding on any 3d printer. 1 × ender 3 leadscrew nut t8*8.. This is also the likely cause for binding on any 3d printer.

Only tighten it to remove any play, but not any further, the easier it can move the better. So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down. But don't tighten it as tight as it was before, that way you can adjust it if necessary. It's a bit awkward but you'll get it. This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. Only tighten it to remove any play, but not any further, the easier it can move the better. You tighten the nut to remove any play in the slides. 24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday. This is also the likely cause for binding on any 3d printer.. An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis.

Only tighten it to remove any play, but not any further, the easier it can move the better. This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm. An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis... 05/08/2019 · it should be the same.

24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday... This is also the likely cause for binding on any 3d printer. But don't tighten it as tight as it was before, that way you can adjust it if necessary. 05/08/2019 · it should be the same. This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough. You tighten the nut to remove any play in the slides.. You tighten the nut to remove any play in the slides.

24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday... 24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday. 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm. I wrote an extensive post on how to fix all of this that you should definitely check out as well: 1 × ender 3 leadscrew nut t8*8... So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down.

An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis. 05/08/2019 · it should be the same. Too tight and the stepper motors will have trouble or be unable to move the axis.

Too tight and the stepper motors will have trouble or be unable to move the axis. I experienced two different printers. 24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday. This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to... This is also the likely cause for binding on any 3d printer.

So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down.. Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough. I experienced two different printers. You tighten the nut to remove any play in the slides. An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis. 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm. Too tight and the stepper motors will have trouble or be unable to move the axis.

But don't tighten it as tight as it was before, that way you can adjust it if necessary. Only tighten it to remove any play, but not any further, the easier it can move the better. 05/08/2019 · it should be the same. You tighten the nut to remove any play in the slides. I wrote an extensive post on how to fix all of this that you should definitely check out as well: This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to. Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough. An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis. 24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday. This is also the likely cause for binding on any 3d printer. So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down. I experienced two different printers.

Too tight and the stepper motors will have trouble or be unable to move the axis. Too tight and the stepper motors will have trouble or be unable to move the axis. But don't tighten it as tight as it was before, that way you can adjust it if necessary. I experienced two different printers. Only tighten it to remove any play, but not any further, the easier it can move the better. Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough. 05/08/2019 · it should be the same. 24/08/2018 · so i recently purchased two creality ender 3's and assembled them yesterday. This can be caused by the z axis being slightly rotated, by the eccentric nuts being either too tight or too loose, or by a slight misalignment between the x axis and the carriage that the extruder is attached to.. I experienced two different printers.

1 × ender 3 leadscrew nut t8*8. So with a wrench holding the eccentric nut, you'd loosen that, then turn your eccentric nut and then tighten that center bolt back down. It's a bit awkward but you'll get it. Too tight and the stepper motors will have trouble or be unable to move the axis. You tighten the nut to remove any play in the slides. 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm. Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough. I wrote an extensive post on how to fix all of this that you should definitely check out as well: An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis. 1 × ender 3 leadscrew nut t8*8.. An eccentric nut is different from a regular one because the hole in the nut is skewed to one side and when you turn it, it pushes the wheel/roller closer or farther away from the axis, and this allows you to adjust how tightly the whole roller assembly will be grabbing on to the axis.

I experienced two different printers. But don't tighten it as tight as it was before, that way you can adjust it if necessary. 1 × ender 3 leadscrew nut t8*8. Only tighten it to remove any play, but not any further, the easier it can move the better. 18/07/2019 · 1 × ender 3 leadscrew t8*8 l365mm. Grab it and wiggle it around, if there is any play in there then its not tight enough, once it doesnt move anymore and there is no play, then its good enough. This is also the likely cause for binding on any 3d printer. 05/08/2019 · it should be the same. You tighten the nut to remove any play in the slides... But don't tighten it as tight as it was before, that way you can adjust it if necessary.